R204101

Inner Tube Valve: Overview, Characteristics & Applications

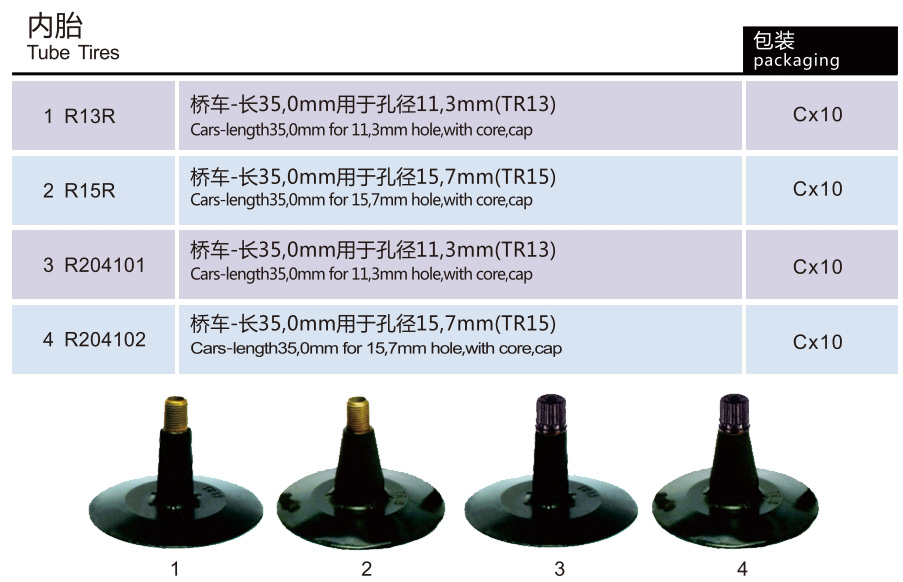

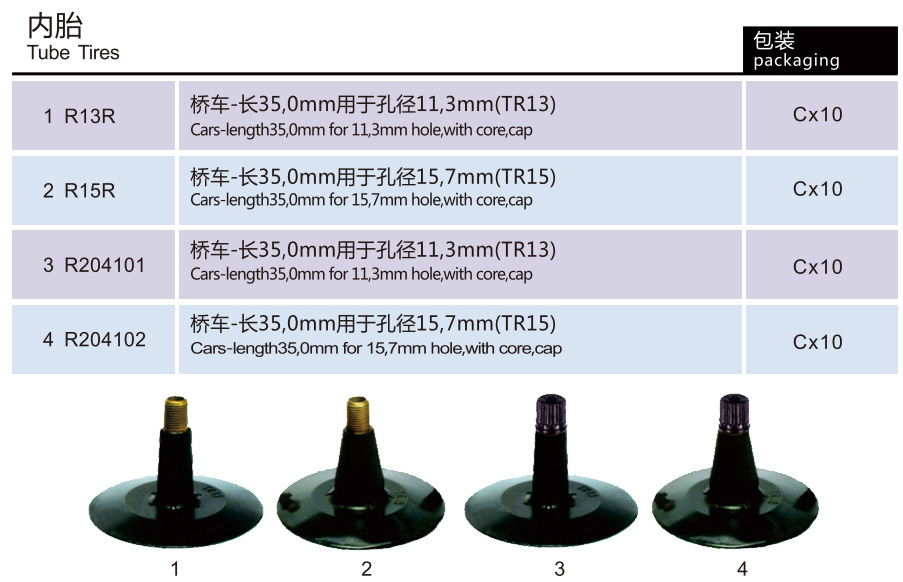

The inner tube valve is a specialized air valve designed for inner tubes, primarily responsible for controlling the inflow and outflow of gas. Its core functions include adjusting tire pressure to meet usage requirements and maintaining vehicle stability during operation. Below is a detailed introduction to its key characteristics and typical application scenarios.

1. Key Characteristics of Inner Tube Valves

Material Diversity: Inner tube valves are commonly manufactured using two types of materials—plastic and metal. Plastic valves offer advantages such as lightweight construction and easy installation, making them suitable for scenarios with lower pressure demands. Metal valves, by contrast, exhibit higher durability and structural stability, making them ideal for long-term use and high-pressure environments.

Diverse Types: To adapt to different vehicles and tire specifications, inner tube valves are available in multiple types, including ordinary valves (for basic low-pressure applications), threaded valves (for secure connection and anti-loosening), and through valves (for specialized tire structures). This variety ensures compatibility with a wide range of equipment.

High Pressure Resistance: A critical performance feature of inner tube valves is their ability to withstand a specific range of air pressure. This resistance ensures the inner tube functions normally under standard operating conditions and effectively reduces the risk of tire blowouts caused by valve failure under pressure.

Anti-Leakage Performance: The structural design of inner tube valves incorporates anti-leakage mechanisms (such as tight-sealing cores and precision fittings). This design effectively prevents unintended gas leakage, maintaining stable tire pressure and ensuring the normal operation of the vehicle or equipment.

2. Typical Applications of Inner Tube Valves

Automobiles: Car tires require regular inflation to maintain optimal pressure, and the inner tube valve serves as a core component of the car’s air inflation system. It ensures accurate pressure adjustment, which is crucial for enhancing driving safety (reducing braking distance) and improving ride comfort (absorbing road vibrations).

Bicycles: Bicycle tire pressure needs to be adjusted based on factors such as road conditions (e.g., rough roads require lower pressure for better shock absorption) and rider weight. The inner tube valve enables precise control of gas inflow and outflow, ensuring smooth riding and reducing fatigue during travel.

Motorcycles: Motorcycle inner tube valves play a vital role in maintaining tire pressure, which directly affects the vehicle’s handling (e.g., cornering stability) and safety. By preventing insufficient tire pressure, the valve avoids risks such as poor control or tire damage during high-speed operation.

Construction Machinery: Tires of construction machinery (e.g., excavators, loaders) operate under heavy loads and harsh working conditions. Regular maintenance of inner tube valves is essential to ensure stable tire pressure, which in turn guarantees the smooth and safe operation of the machinery, reducing downtime due to tire-related issues.