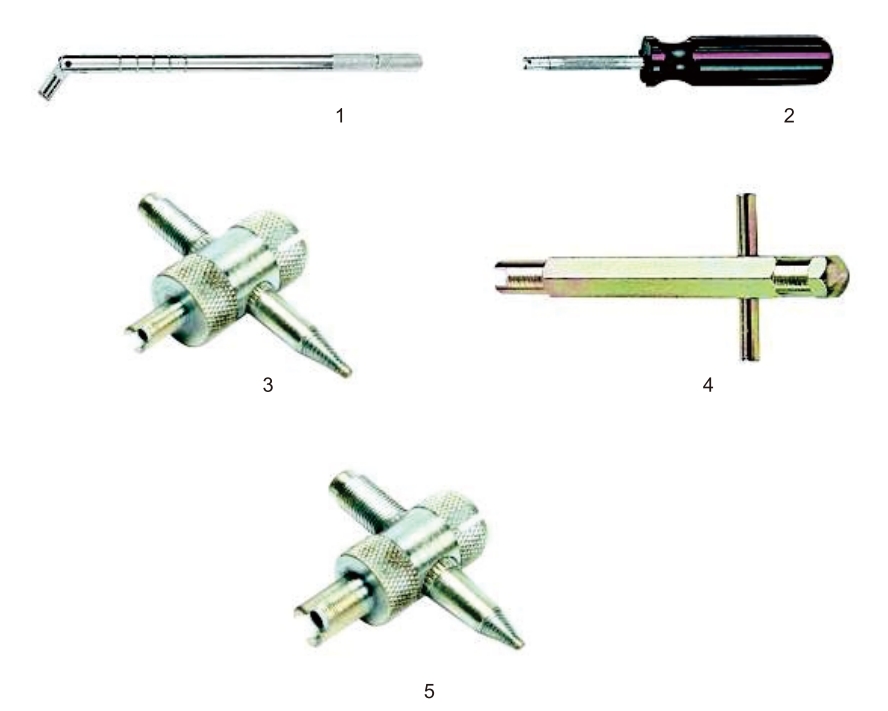

R2688C

Accessory Pneumatic Screwdriver: Characteristics & Applications

The accessory pneumatic screwdriver is a specialized tool for tightening or loosening screws, typically used with pneumatic (air-powered) tools (correcting "electric or manual" to match its pneumatic nature). It enhances efficiency and precision in assembly and maintenance tasks across multiple industries.

As a key accessory for pneumatic tools, this screwdriver converts air pressure into rotational force to drive screws. Unlike manual screwdrivers, it reduces operator fatigue while improving tightening consistency—making it a staple in high-volume production and precision maintenance. Its design focuses on adaptability, durability, and accuracy to meet diverse industrial needs.

Core Characteristics

High Precision & Efficiency

Delivers high-speed rotational force and precise torque control, ensuring screws are tightened to uniform specifications. This reduces errors (e.g., over-tightening or under-tightening) and speeds up workflow—critical for assembly line productivity.

Lightweight & Flexible

Features a simple, compact structure with lightweight materials, making it easy to handle. Its ergonomic design allows operation in narrow spaces (e.g., inside electronic devices or automotive components) and supports frequent movement without straining the user.

Durable & Stable Quality

Constructed from high-grade materials (e.g., hardened steel for the bit, impact-resistant plastic for the housing), it withstands repeated use and minor impacts. This durability ensures long service life, reducing replacement costs for users.

Strong Versatility

Compatible with screws of different specifications (e.g., cross-head, flat-head, hexagonal) and sizes. It can be paired with various pneumatic tool models, adapting to tightening tasks in mechanical manufacturing, electronics, automotive, and household product industries.

Practical Applications

Industrial Assembly Lines

Widely used in assembly lines for mechanical manufacturing, automotive production, and electronic equipment (e.g., smartphones, home appliances). It enables rapid, uniform screw tightening, improving production efficiency and product consistency—critical for meeting large-scale production targets.

Equipment Repair & Maintenance

Essential for technicians in repairing machinery, automobiles, and electronic devices. It simplifies the removal and reinstallation of screws, even in hard-to-reach areas, reducing repair time and labor costs. Its precision also prevents damage to delicate components during maintenance.

Household & Small-Scale Production

Suitable for small workshops or DIY enthusiasts manufacturing household products (e.g., furniture, wooden crafts). It balances power and ease of use, making it ideal for tasks that require consistent screw tightening without professional industrial equipment.