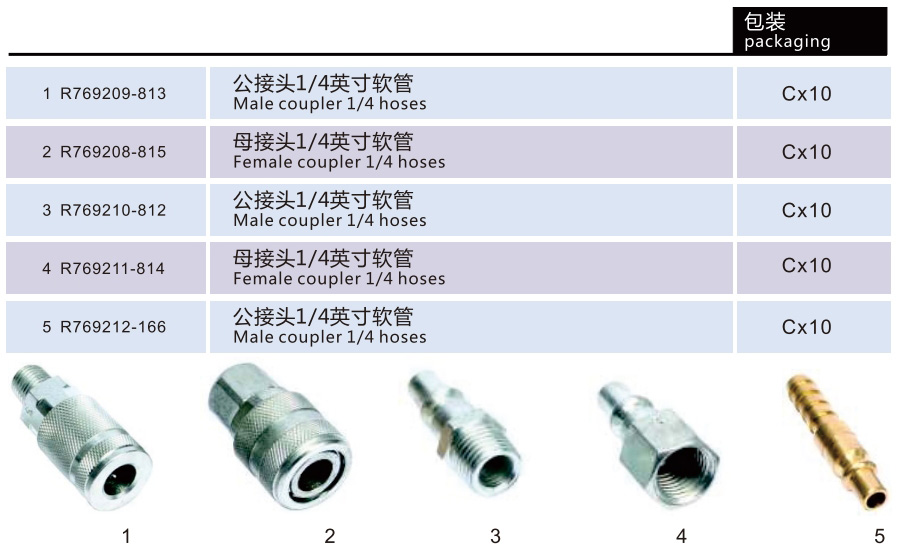

R769210-812

Quick Connector: Core Characteristics & Material Options

A quick connector is a specialized device for connecting or disconnecting pipeline systems, designed to enable fast, labor-saving assembly and disassembly of pipelines. It is widely used in industrial, civil, and mechanical fluid/gas transmission scenarios to improve operational efficiency.

Traditional pipeline connections often require complex tools (e.g., wrenches, welders) and time-consuming operations, while quick connectors simplify the process with optimized structures—ideal for scenarios that need frequent pipeline maintenance, replacement, or temporary connection. Their design integrates speed, reliability, and adaptability, making them a key accessory in modern pipeline systems.

Key Characteristics

Ultra-Fast Connection & Disassembly

Adopts threaded or clamping structures that allow pipeline connection or disassembly in just a few seconds—no need for lengthy tightening or dismounting of multiple components. This significantly reduces labor time, especially in high-volume assembly lines or emergency maintenance.

High Reliability & Sealing

Made of high-quality materials (e.g., stainless steel, engineering plastic) with precision-machined sealing components (e.g., O-rings, rubber gaskets). It effectively prevents fluid/gas leakage and maintains stable connection performance even under pressure fluctuations or vibration.

Diverse Model Options

Available in multiple models to match different pipeline layouts and functions, including right-angle joints (for narrow spaces), T-joints (for branch pipeline connections), and turning joints (for flexible angle adjustment). This ensures compatibility with various pipeline systems.

Simple Operation (No Specialized Tools)

Features a streamlined structure that requires no professional tools or technical training. A single person can complete connection/disassembly independently, reducing reliance on skilled workers and lowering operational thresholds for both industrial and civil use.

Material Selection (Based on Scenarios)

Customizable Materials for Different Pipeline Environments & Media

Stainless Steel

Suitable for high-pressure, corrosive environments (e.g., chemical pipelines, marine engineering, oil transmission) due to its excellent rust resistance, high strength, and temperature tolerance.

Copper

Ideal for low-to-medium pressure fluid transmission (e.g., household water supply, refrigeration systems, air conditioning pipelines) with good thermal conductivity, ductility, and sealing performance.

Plastic (PP, PVC, POM)

Used in low-pressure, non-corrosive scenarios (e.g., agricultural irrigation, household drainage, medical fluid transmission) due to its lightweight, low cost, and resistance to weak acids/alkalis.