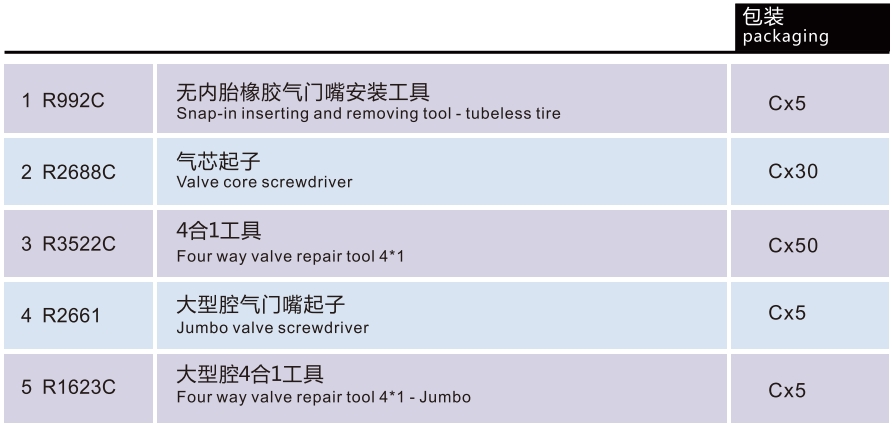

R992C

Tubeless Tire Valve: Characteristics & Applications

The tubeless tire valve is a core component for tubeless tires—devices that integrate the tire body and inner tube into one, eliminating traditional rubber inner tubes. This valve connects the tire to inflation tools, ensuring precise air pressure control and stable tire operation across various vehicles.

A tubeless tire abandons the traditional separate rubber inner tube, instead using a flexible tire body that adheres directly to the wheel rim. It prevents air leakage through thickened sidewalls and a specially designed airtight liner—this structure is now widely adopted in bicycles, motorcycles, passenger cars, trucks, and other vehicles. The tubeless tire valve, as the key interface for inflation and pressure maintenance, directly affects the tire’s safety and service life.

Core Characteristics of Tubeless Tire Valve

Anti-Leakage Airtight Design

Adopts a specialized airtight structure (such as precision valve cores and sealing gaskets) to effectively prevent air leakage. It maintains stable tire pressure for long periods, avoiding frequent inflation and ensuring consistent driving performance.

High Temperature & Pressure Resistance

Made of high-performance materials (e.g., reinforced rubber, metal alloys), it withstands extreme environments—such as high temperatures from long-distance driving or high pressure during inflation—without deformation or failure.

Wear & Corrosion Resistance

The valve surface undergoes special treatments (e.g., electroplating, anti-corrosion coating) to resist wear from frequent inflation operations and corrosion from moisture, road salts, or other harsh substances, extending its service life.

Strong Adaptability

Available in multiple specifications to match different vehicle types (bicycles, motorcycles, cars) and tire sizes. It can be flexibly adjusted during inflation, making the operation convenient and efficient for various scenarios.

Safe & Reliable Quality

Undergoes strict quality testing and industry certification (e.g., automotive safety standards). It avoids risks like valve breakage or sudden air leakage during use, ensuring driving safety.

Wide Application Range

Bicycles & Motorcycles

Essential for tubeless tires on bicycles (mountain bikes, road bikes) and motorcycles. It maintains stable tire pressure to adapt to rough roads or high-speed riding, improving handling and reducing the risk of punctures.

Passenger Cars

Standard equipment for modern car tubeless tires. It ensures precise air pressure control, which is crucial for fuel efficiency, tire wear reduction, and driving comfort—directly affecting the vehicle’s overall performance and safety.

Commercial Vehicles (Trucks, Vans)

For heavy-duty tubeless tires on trucks and vans, the valve must withstand higher pressure and heavier loads. Its durability and anti-leakage performance ensure stable tire operation during long-haul transportation, reducing maintenance downtime.