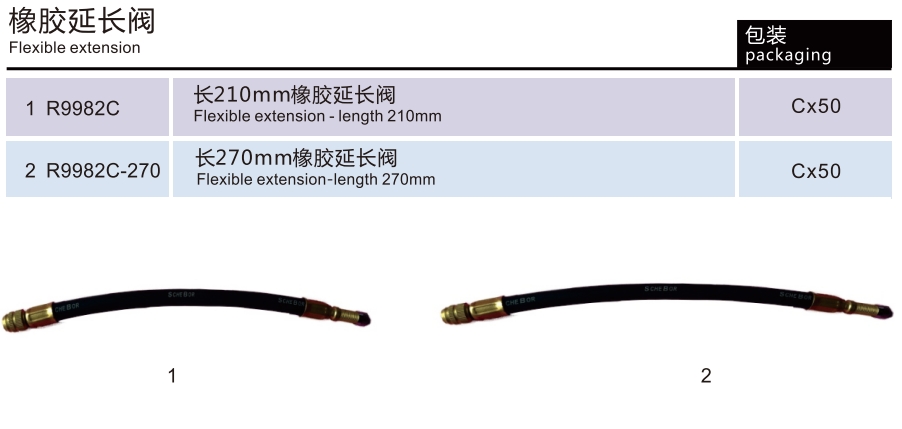

R9982C

Rubber Extension Valve: Characteristics & Applications

The rubber extension valve is a new-type valve designed for fluid control scenarios. It integrates excellent material performance and practical structural design, making it suitable for both industrial and civil fields. Below is a detailed introduction to its core characteristics and application scenarios.

Core Characteristics

Superior Material Performance

Made of high-quality rubber material, it has good elasticity and wear resistance—effectively ensuring the valve's long-term sealing performance and extending its service life.

Simple & Easy to Maintain

With a simple structural design, it features convenient operation, easy maintenance, and quick repair—greatly reducing daily maintenance costs for users.

Compact Space-Saving Design

The compact overall structure occupies a small installation space, making it particularly suitable for pipeline systems with limited installation areas.

Precise Fluid Control

The flow rate and pressure of the fluid can be flexibly adjusted according to actual needs, significantly improving the control accuracy of the entire fluid pipeline system.

High Temperature & Corrosion Resistance

It exhibits excellent resistance to high temperatures and chemical corrosion, enabling stable operation in various harsh industrial environments.

Practical Applications

Industrial Pipeline Systems

Widely used in pipeline systems of petroleum, chemical, metallurgy, and power industries—responsible for accurately controlling fluid flow and pressure to ensure stable production processes.

Civil Infrastructure

Applied in civil fields such as sewage treatment, tap water supply, central air conditioning systems, and heating systems—guaranteeing the smooth operation of daily life-related fluid transmission.

Food & Pharmaceutical Industries

Plays an important role in the production processes of food and pharmaceutical industries—its excellent sealing and material safety ensure compliance with hygiene standards and normal operation of production lines.

Special Environmental Scenarios

Due to its good sealing, wear resistance, and corrosion resistance, it is also suitable for pipeline systems in special environments such as offshore oil platforms (resisting salt spray corrosion) and high-altitude areas (adapting to low-temperature and low-pressure conditions).